520 cm

Max. print width

353 m²/hr

Max. productivity

up to 600 dpi

Resolution

CMYK + optional lc, lm, lk, white

Colours

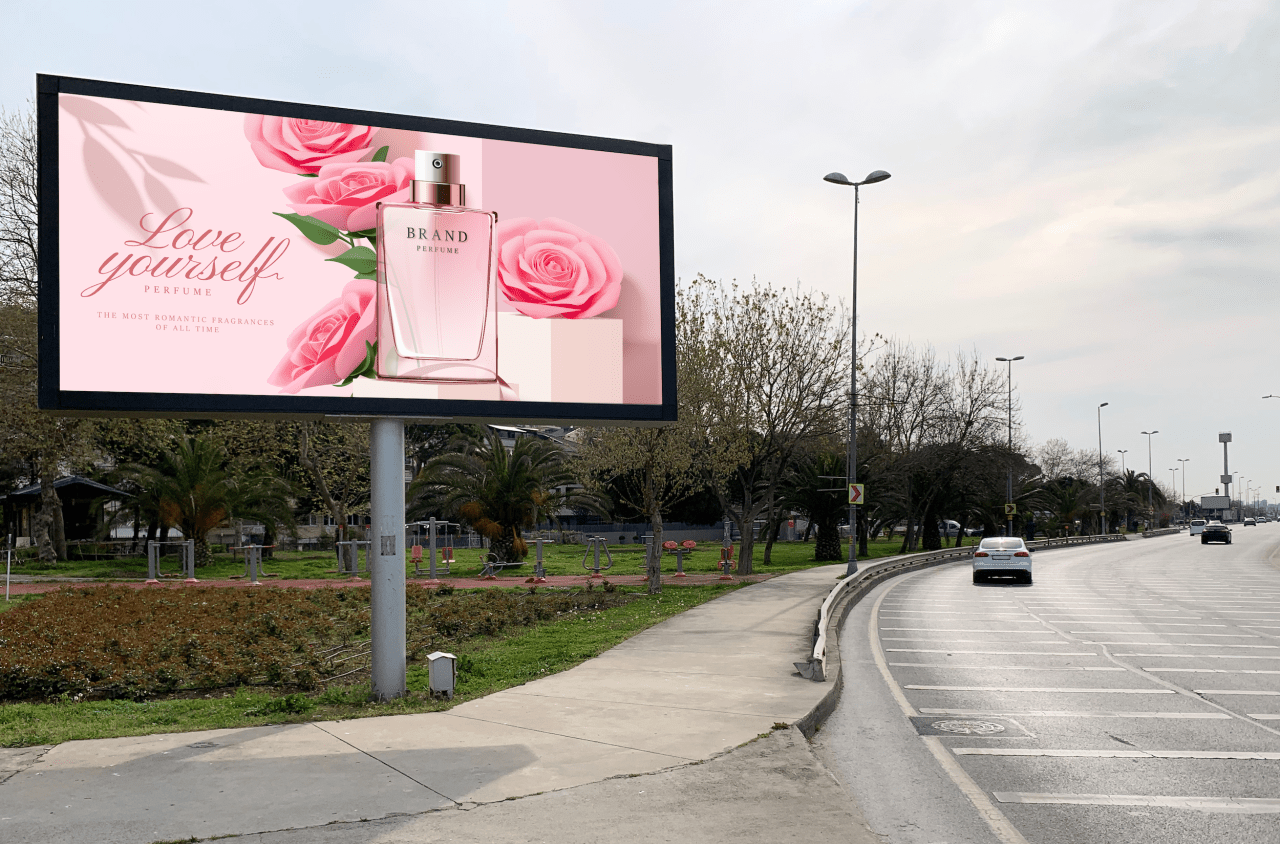

Print beautiful graphics at production speeds

Accelerate your productivity and print quality at the best cost of ownership with the EFI™ Matan 5 superwide roll-to-roll UV printer. It offers maximum versatility for a wide range of indoor and outdoor applications.

Offer customers more high-value applications

Highlights

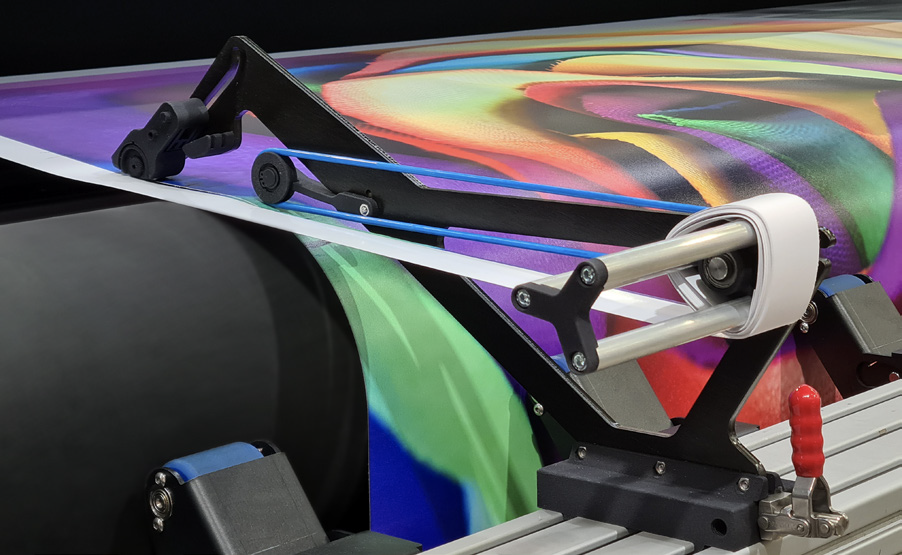

Productive roll-to-roll printing

Quick and easy media loading that handles a wide variety of flexible substrates. Roll-to-roll, free-fall, and multi-roll (3 rolls of 160 cm) at production speeds up to 352 m2 per hour.

White ink and multi-layer printing

Superb white ink printing performance in single- and multi-layer print modes.

Media savings

Unique roll loader for up to 300% better media utilization — only 40 cm of wasted material on every roll loading.

Inline finishing

EFI’s unique roll-to-roll workflow automates the complete printing and finishing process on the fly and in a single system.

Fiery Driven

Built-in Fiery® SE digital front end with color management workflow and RIP optimised for EFI printers.

Learn more >

Power Tools to boost your capabilities and profits

Y-slitter – for the vertical trimming of margins or slitting media into multiple jobs, minimising media waste and increasing the printing area.

- Simultaneous printing and media cutting on the Y-axis

- Modifiable configurations include:

- Single-bladed for trimming margins

- Double-bladed for slitting of single media into two jobs (blades are fixed 8 mm apart)

- Simple and easy installation with no tools required

- Easy manual adjustment of the slitter position along the printer table

- Retractable blades for maximum safety

- And waste collectors to roll up trimmed remnants, increasing overall productivity and eliminating the mess

X-cutter – unique roll-to-sheet horizontal cutter incorporated in the printer.

- Automatically cuts media on the X-axis between jobs on the fly

- Controlled via the front-end software

- Does not affect productivity

- Saves valuable time at the finishing station

- Replaces expensive cutting equipment and saves space

- Prevents finishing errors and increases yield

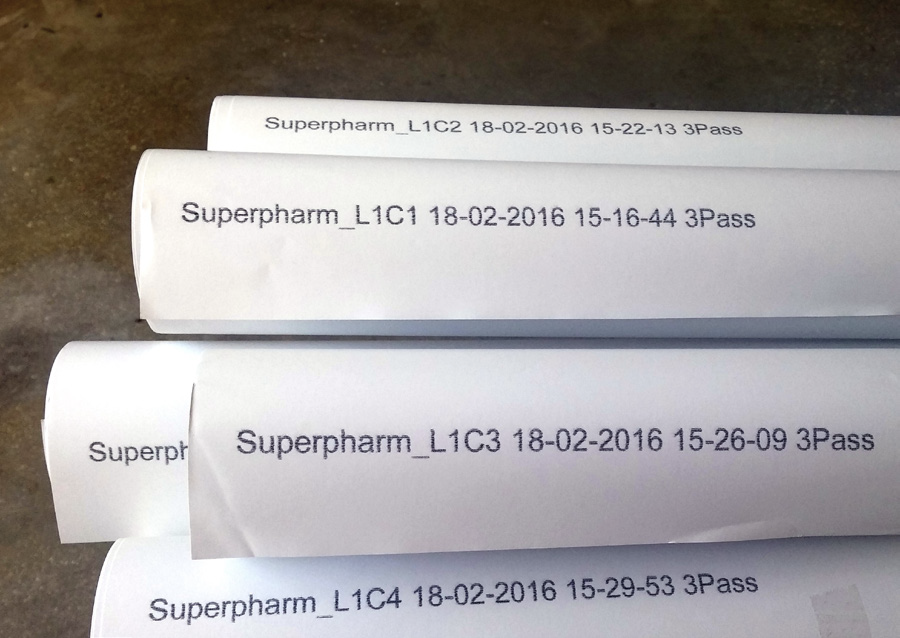

ID backprint – a device that prints file information on the back of the media, facilitating the identification of finished jobs for packing, shipping, and installation.

- Printed data includes:

- File ID

- Printing date and time

- Print mode

- Copy number and more

- Eliminates the need for manual labeling

- Helps prevent shipping errors

- Saves time during installation of the printed job

White printing

- Enables printing on coloured and transparent media

- Opens up a myriad of creative possibilities

- Instant uptime of white printheads, thanks to advanced circulation system in the ink tanks and along the entire ink system

- Multiple white print modes for various challenging applications:

- White only

- White as background

- White on top of colour

- White for backlit applications (C-W-C)

- Five-layer printing (C-W-B-W-C) for blockout printing on clear

- Various additional three- and five-layer print modes

Seven-colour printing

- Enabled by adding three light colours: light cyan, light magenta, and light black

- Based on the existing printhead configuration, without adding more heads

Benefits

- Expanded colour gamut

- Smooth gradient transitions

- Vivid and crisp colours

- Fine details

- Smooth skin tones

Automatic blockout printing – an automatic system that enables printing on both sides of opaque blockout media, resulting in excellent registration between sides.

- Accuracy of ≤ 5 mm over 10 linear metres

- Includes an optical sensor system, dedicated electronics and software

- Simple, easy, and fully automatic system

- Eliminates the need for guesswork and manual manipulation

- Reduces required operator skill level

- Two available workflows, to be defined before printing:

- Head-to-head printing for short jobs where media is rolled back, flipped over, and reinstalled with side B up

- Head-to-tail printing for longer jobs where printed media is collected on a front core, flipped over, and reinstalled with side B up

Notes

- Single-roll printing for side B

- Use of X-cutter and Y-slitters with automatic blockout is limited:

- Slitters – possible according to built-in instructions

- Cutter – can be used for side B

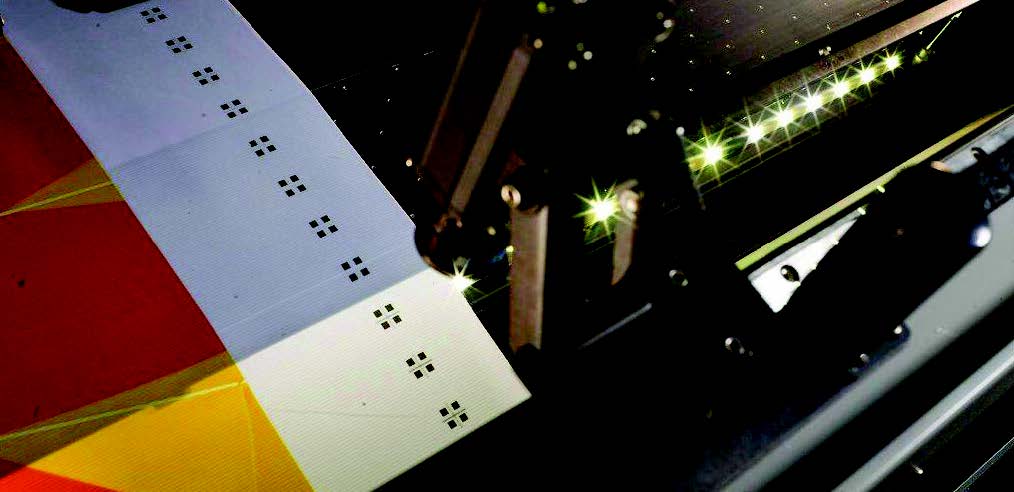

Automatic backlit printing – Automatic, patented system for perfectly aligned double-sided backlit printing on backlit media.

- Accuracy of ≤ 2 mm over 10 linear meters

- Camera-guided software automatically correct registration on x, y, and tilt axes

- Includes two cameras, LED strip along printing table, and dedicated software

- Simple, easy, and fully automatic system

- Eliminates the need for guesswork and manual manipulation

- Reduces required operator skill level

Three-metre super duty winder – fully integrated unwinder or rewinder option for EFI VUTEk roll-to-roll 3m and 5m printers.

- Enables working with heavy 3 m media rolls up to 793 kg

- Enables continuous, uninterrupted work without stopping to change rolls

- Increases productivity in high volume runs due to less make ready

- Equipped with dancer and external motor

- Material width: 320 cm

- Maximum media diameter: 70 cm

- Standard 3 in core; optional 6 in core

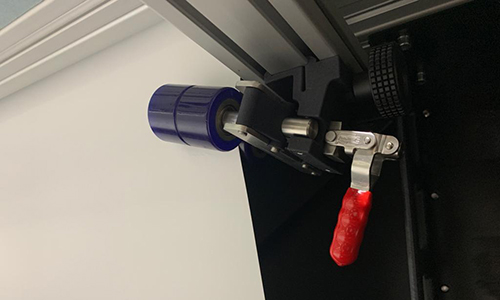

Media spreaders – a pair of clamp-like devices that stretch the media sideways to enable neat media inlet to the printer.

- Helps prevent potential media wrinkles

- Improves media advance

- Facilitates printing on various types of challenging media

- Easy to install at both ends of the press beam on the rear of the printer

- Position and tilt angle are adaptable to the media type and width

Wrinkle analyser – helps avoid printhead strikes caused by media wrinkles, saving time and money by preventing ruined jobs and enabling the use of lower-cost media.

- Media height detector identifies a media wrinkle before it reaches the printhead

- The front-end software prompts the user to raise the carriage just enough to avoid a head strike that may ruin the job and, then, to resume printing

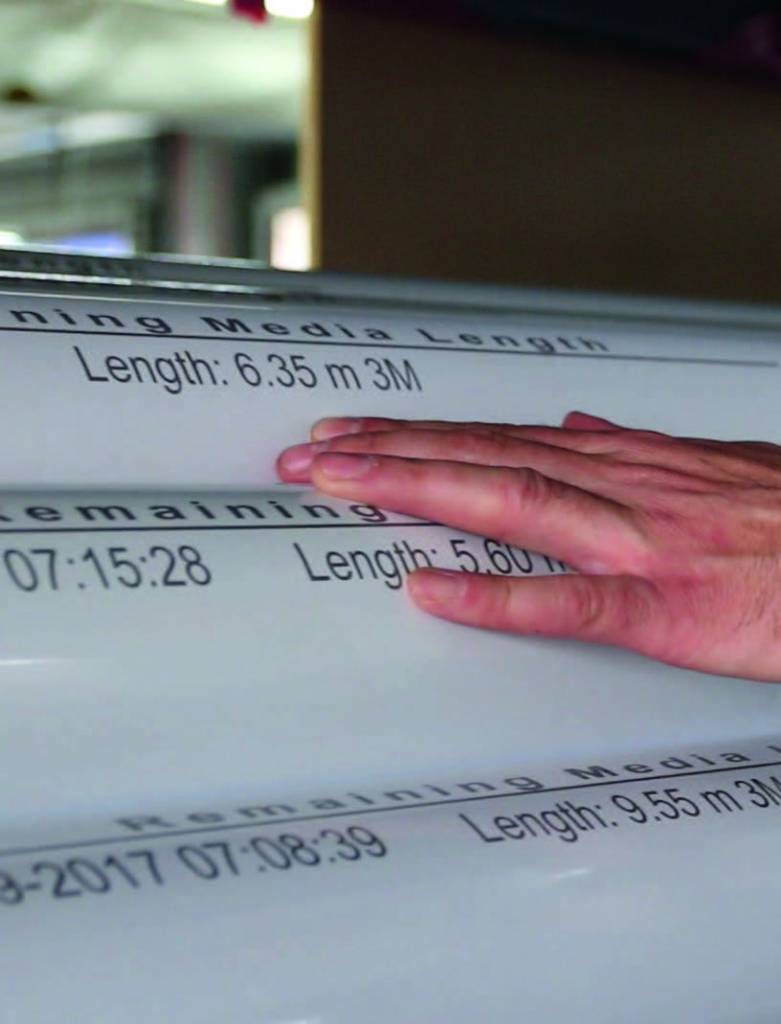

Media saving wizard

- Designed to improve media stock management

- The user enters the length of the media each time a new or partially used roll is loaded into the software

- Before the media is removed from the printer, a label with the remaining media length is printed on the rim of the roll

- The software will alert the user before starting a job if the remaining media on the roll is insufficient for the job